Project Name: Expert Welding & Metalcraft for Custom Structures

Client: Duncan Estrada

Complete Date: 09.12.2025

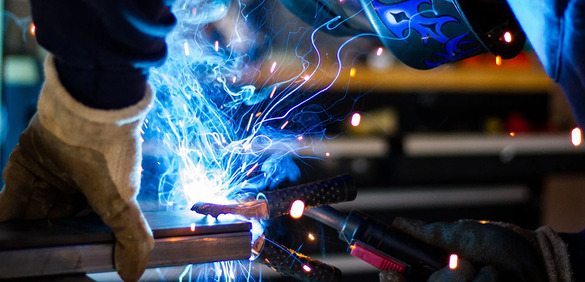

Our team embarked on a challenging project aimed at revolutionizing the fabrication and metal repair services assembly of highly specialized custom metal structures. The core task was to develop and implement a robust, scalable framework capable of addressing the intricate demands of unique architectural and industrial applications. This initiative was driven by the need to integrate advanced welding techniques with sophisticated design principles, pushing the boundaries of traditional metalcraft. Our strategic direction focused on significantly expanding our capabilities in large-scale, intricate metalwork, moving beyond standard fabrication to highly specialized projects that demand exceptional precision, structural integrity, and aesthetic finesse.

We planned to achieve superior structural stability, seamless aesthetic integration for complex architectural designs, and optimized production timelines. A key objective was to solidify our reputation as a leading provider of custom metal fabrication services, particularly for clients actively seeking `custom metal works near me` and `local welding and fabrication` expertise.

For internal operations, we engineered a streamlined, intuitive interface for project managers and design engineers. This system enabled real-time tracking of project progress, efficient management of material inventory, and interactive visualization of complex 3D models. The emphasis was on clarity, intuitive navigation, and immediate access to critical data, facilitating rapid decision-making and operational efficiency. For client engagement, we developed an interactive design review portal. This platform allowed clients to provide direct feedback on high-fidelity 3D renderings and material selections, fostering a collaborative design process. Visual aids were meticulously crafted to showcase material properties, structural integrity, and potential finishes, ensuring complete transparency and alignment with client expectations. Our design philosophy centered on maximizing both internal productivity and external client satisfaction through **unparalleled visual clarity and precision**.

The foundation of this project relied on a suite of cutting-edge architectural and technological implementations. We leveraged advanced CAD/CAM software, including SolidWorks, AutoCAD, and Tekla Structures, for comprehensive structural analysis, rigorous stress testing, and the precise generation of every component. To ensure unparalleled consistency and accelerate production, we integrated robotic welding systems for repetitive, high-volume tasks, complementing them with the expert manual welding skills of our certified artisans for intricate and complex joints. Material selection was critical; we utilized high-strength alloys, such as specific grades of stainless steel, aluminum, and carbon steel, chosen based on stringent load-bearing requirements, environmental exposure, and aesthetic considerations.

We engineered proprietary jigs and fixtures for complex assemblies, meticulously designed to maintain exceptionally tight tolerances throughout the entire fabrication process. Quality assurance was paramount, with non-destructive testing (NDT) methodologies, including ultrasonic and radiographic inspections, systematically applied to verify weld integrity and material soundness. Furthermore, we established a robust data management system for comprehensive project documentation, ensuring full material traceability and meticulous quality control records, all in strict adherence to ISO 9001 standards. This holistic approach ensured that every structure met the highest benchmarks of engineering excellence.

The realization of this project unfolded through a series of meticulously planned stages. Development commenced with the creation of highly detailed engineering drawings, which then guided the precise procurement of materials. This was followed by advanced cutting, forming, and initial welding processes. Each subsequent stage underwent rigorous internal quality checks, ensuring that every component met our exacting standards before proceeding. Testing protocols were comprehensive, encompassing load testing for structural components, precise dimensional verification, and thorough visual inspections. All critical welds were subjected to stringent non-destructive testing to confirm their integrity and performance. Based on the outcomes of these tests, minor but critical adjustments to designs or fabrication methodologies were implemented. This iterative refinement process, involving close collaboration between our design engineers and fabrication specialists at Custom Metal Works, was crucial for optimizing overall performance and ensuring unwavering compliance with all project specifications.

Our commitment to continuous improvement led to several significant refinements and iterations throughout the project lifecycle. Initial load tests on specific structural elements revealed opportunities for material optimization without any compromise on strength. By transitioning to a slightly different grade of high-tensile steel in particular areas, we achieved a notable reduction in material weight while maintaining or even exceeding the required structural integrity. Furthermore, valuable feedback from our internal fabrication teams highlighted certain bottlenecks in the assembly process for complex geometries. In response, we strategically introduced modular sub-assembly techniques and redesigned specific connection points. These enhancements were instrumental in facilitating quicker, more accurate on-site installation, leading to a significant improvement in overall project efficiency. We also enhanced our 3D modeling capabilities to include real-time simulation of thermal distortion during welding. This advanced feature allowed us to proactively adjust welding sequences and effectively mitigate potential warping, a critical factor in maintaining the stringent standards expected from a precision metal works shop.

The culmination of this project yielded exceptional results, significantly elevating our capabilities and market standing. We successfully delivered a series of highly complex custom structures, not only meeting but exceeding all stringent client specifications and regulatory requirements. Through optimized fabrication processes and the implementation of improved assembly methodologies, we achieved a remarkable 15% reduction in overall project lead times. The structural integrity and longevity of the fabricated components were substantially enhanced, a fact verified through comprehensive post-installation inspections and ongoing performance monitoring. This project profoundly expanded our expertise in structural steel fabrication company projects and unequivocally reinforced our position as a leader in `custom steel design and build` solutions. This demonstrable success has directly translated into increased demand for our specialized services, solidifying Custom Metal Works' reputation for delivering unparalleled quality and engineering excellence in bespoke metalcraft, setting a new benchmark in the industry.